90% Drift-Reducing Nozzles: An Essential Tool for Responsible Spraying

Operation of Drift-Reducing Nozzles

The use of drift-reducing nozzles is currently the most widespread technology for reducing drift during pesticide applications. These nozzles enable uniform spraying and produce appropriate droplets, thereby significantly reducing their dispersion in the air.

Agronomic and Environmental Benefits

Air-injection nozzles with 90% drift reduction, listed on the official list of approved nozzles for “untreated buffer zone reduction,” offer a dual benefit for pre-emergence root herbicides: they prevent air and water contamination while ensuring very good efficacy. Indeed, the droplet size helps reduce drift while maintaining the expected efficacy, and the spray volume per hectare does not affect the performance of root herbicides.

Regulatory and Safety Importance of Drift-Reducing Nozzles

Beyond their technical benefits, these nozzles are essential for meeting regulatory requirements, limiting environmental impact, and ensuring the safety of the applicator and the surrounding area, while maintaining optimal agronomic efficacy.

Current Regulations on the Use of Plant Protection Products (since November 2023)

Prosulfocarb: An Herbicide Under Enhanced Surveillance

The regulations governing the use of plant protection products have been significantly strengthened in recent years, including the obligation to use drift-reducing nozzles for prosulfocarb application. Indeed, prosulfocarb is the second best-selling herbicide active substance in France and is subject to monitoring under phytopharmacovigilance (ANSES) following contamination of neighboring non-target crops. The drift-reducing nozzle, officially recognized by authorities, is the most effective means of reducing spray drift.

Why Limiting Spray Drift is Essential

Spray drift during the application of plant protection products must be avoided as much as possible. Indeed, in the event of drift, fine spray droplets can end up in undesirable locations. The presence of plant protection products in surface waters or on crops neighboring the treated plot risks causing damage. Furthermore, these droplets can also result in residues on food crops.

New Restrictions Applicable Since November 1st, 2023

Since November 1st, 2023, new restrictions have come into force to regulate its use:

- Use a drift-reducing device during application, primarily air-injection nozzles, referring to the list updated by the Ministry of Agriculture.

- Maintain a distance of 20m with an approved drift reduction device or the use of drift-reducing nozzles, or 10m if using nozzles approved to reduce drift by at least 90%, from people present, residential areas, and activities.

- Wait for the harvest of non-target crops within a 1 km radius : fruit crops (apples, pears), vegetable crops (lamb’s lettuce, spinach…), medicinal crops (burdock, cardoon, chicory…), and others (buckwheat, quinoa, chia, millet, foxtail millet, sorghum).

Farmer Testimonials and Field Feedback

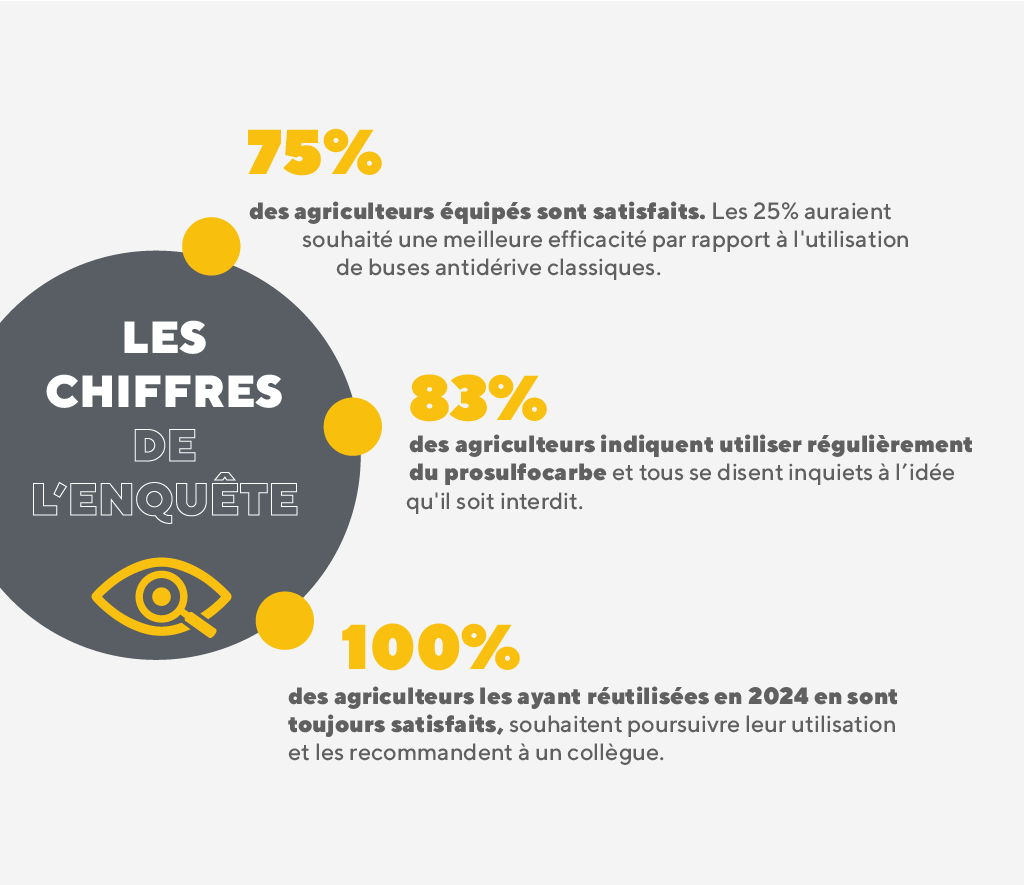

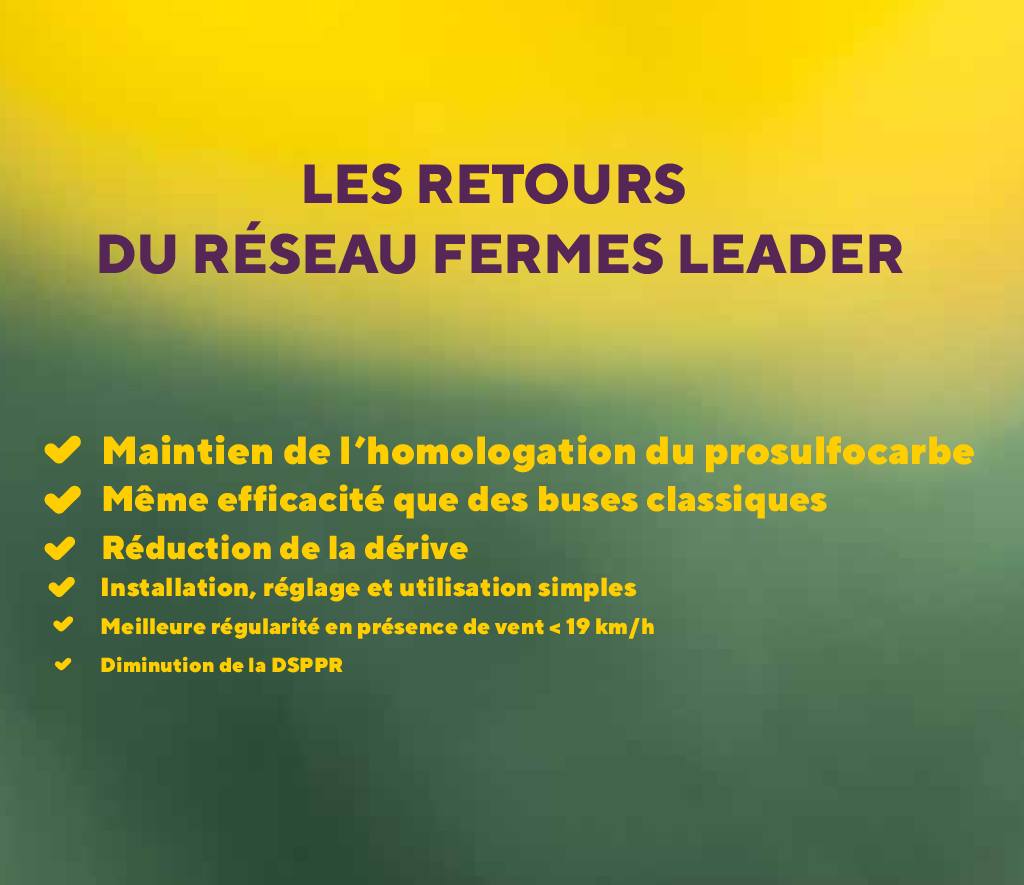

For the 2023-2024 season, Fermes LEADER, in collaboration with Syngenta, launched an evaluation to better understand farmers’ needs and facilitate the adoption of 90% drift-reducing nozzles in the field. This evaluation aimed at several strategic objectives, including field-testing these nozzles to assess their ease of installation and use, as well as the benefits and profitability for agricultural operators.

A year and a half later, an assessment was conducted with the farmers who participated in the project. Their feedback highlights several observations:

- A stable level of satisfaction, with no observed decrease in efficacy.

- Nozzle adjustment deemed easier to adapt spraying.

Some farmers continued using the nozzles in 2024, particularly with prosulfocarb, and report continued satisfaction. They were also used in spring, for example for beet weeding, often in windy conditions. Good mastery of the adjustment allowed for achieving the desired droplet size.

Among those who did not continue the experiment, several reasons are cited:

- Complicated or late management of autumn weeding.

- A lack of time and practicality, particularly due to nozzle changes.

- Higher water consumption and reduced travel speed.

Despite these obstacles, farmers recognize the benefit of having these nozzles available, especially in case of stricter regulations. Prosulfocarb remains identified as a relevant product to continue supporting and encouraging the use of these 90% nozzles.